Description

MONEL Alloy 400

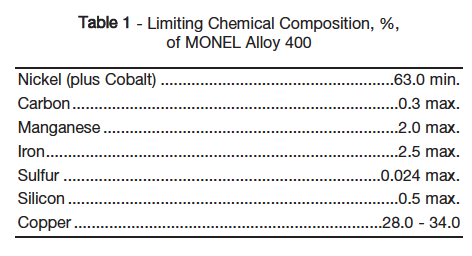

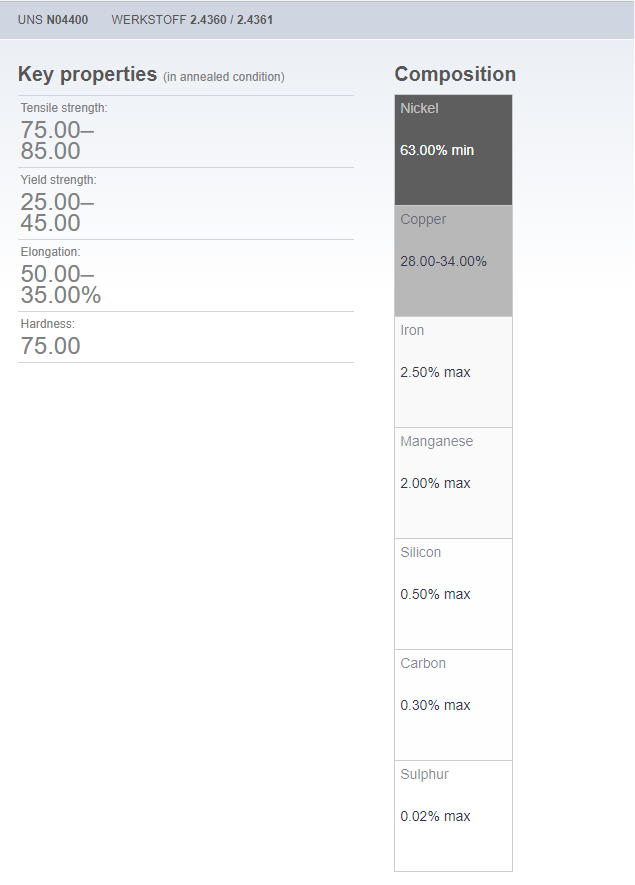

MONEL® alloy 400 was derived directly from the refined ore bodies of Canada and provides a lower cost alternative to commercially pure Nickel due to the Copper content of approximately 30 wt % but retains very similar characteristics to Nickel 200/Nickel 201.

The solid solution alloy can be hardened by cold working, but can be hot worked or cold worked followed by annealing into complex fabrications and welding with an appropriate welding process.

Petroleum distillation tower internals, fasteners and fittings, pumps and valve internals have employed the alloy for over 100 years since its introduction to the market in 1905. The alloy is employed for process vessels, heat exchanger piping, and storage tanks of gasoline and potable water in the marine sector. The spark free nature of the alloy lends itself to high risk situations in the explosives industry, rocketry and the pulp and paper industry. The high mechanical properties, ductility and resistance to atmospheric corrosion lend the alloy to feature as rivets in the construction of aluminium skinned aircraft and aluminium ladders.