Description

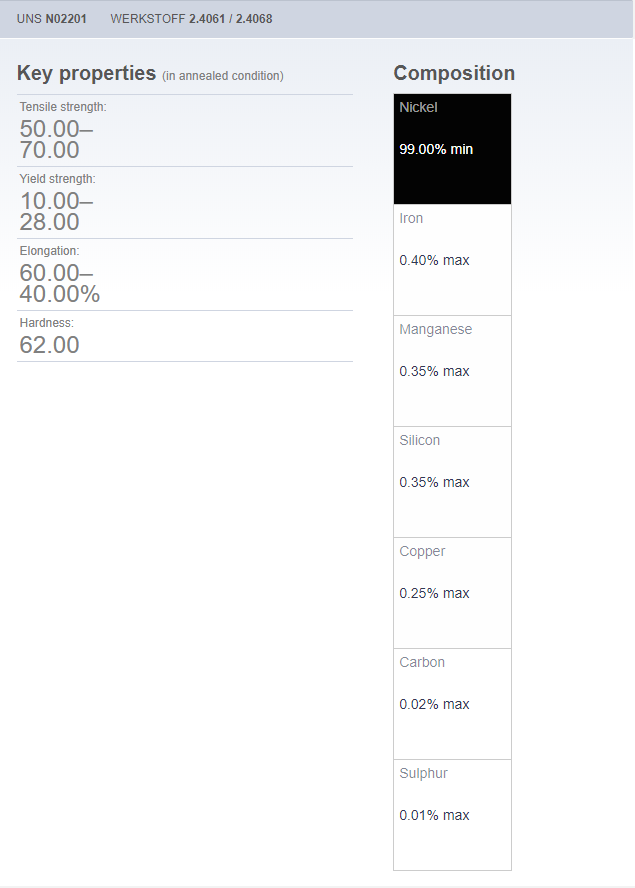

Nickel Alloy 201

Nickel 201 is the low carbon version of Nickel 200 suitable for forming by deep drawing and spinning into combustion boats and the continuous stamping of strip into electronic components. The material is selected for caustic salt evaporators above 315 deg C ( 600 deg F) as the extended exposure of Nickel 200 above this temperature can lead to the formation of graphite. Nickel 201 will not form graphite after extended exposure to temperature providing carbonaceous materials are not in contact with it. The material is however subject to intergranular embrittlement by sulphur compounds above 315 deg C ( 600 deg F) such that machining fluids and external sources of sulphur need to be eliminated to prevent damage during fabrication and subsequent service. Nickel 201 is approved for pressure vessel service ( ASME VIII Div 1) to 1250 deg F.

The alloy has good resistance to a number of acids and alkalies, however its major use lies in the electrolytic extraction of caustic soda from salt solutions and the subsequent concentration processes. With excellent resistance to distilled and natural waters creating a tenacious oxide film the material is used in the food processing industry

Nickel 201 is available in all product forms including bar, plate, sheet, strip, wire, tube and pipe fittings , flanges and fasteners with welding consumables for most welding processes with the exception of oxyacetylene. The alloy can also be brazed and soldered.

Nickel 200/201 is frequently dual certified as a result of processing which provides the strength of Nickel 200 with the stability of the compositional controls of Nickel 201.

Welding consumables

Welding electrodes: 141

Download